Melamine foam is a lightweight porous material with an open porosity rate exceeding 99%, and a highly abrasive foam material made from melamine resin, a thermosetting polymer derived from melamine and formaldehyde.

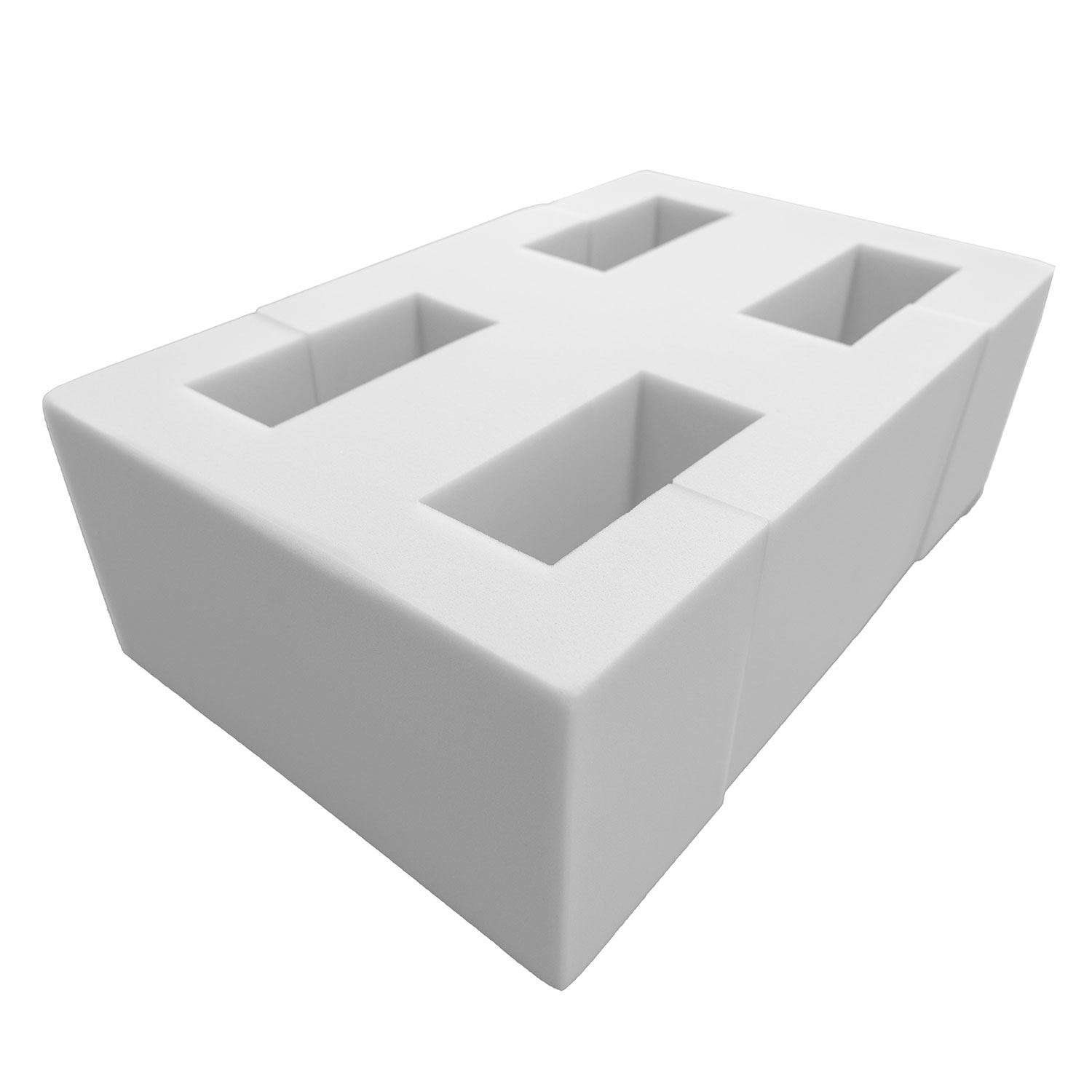

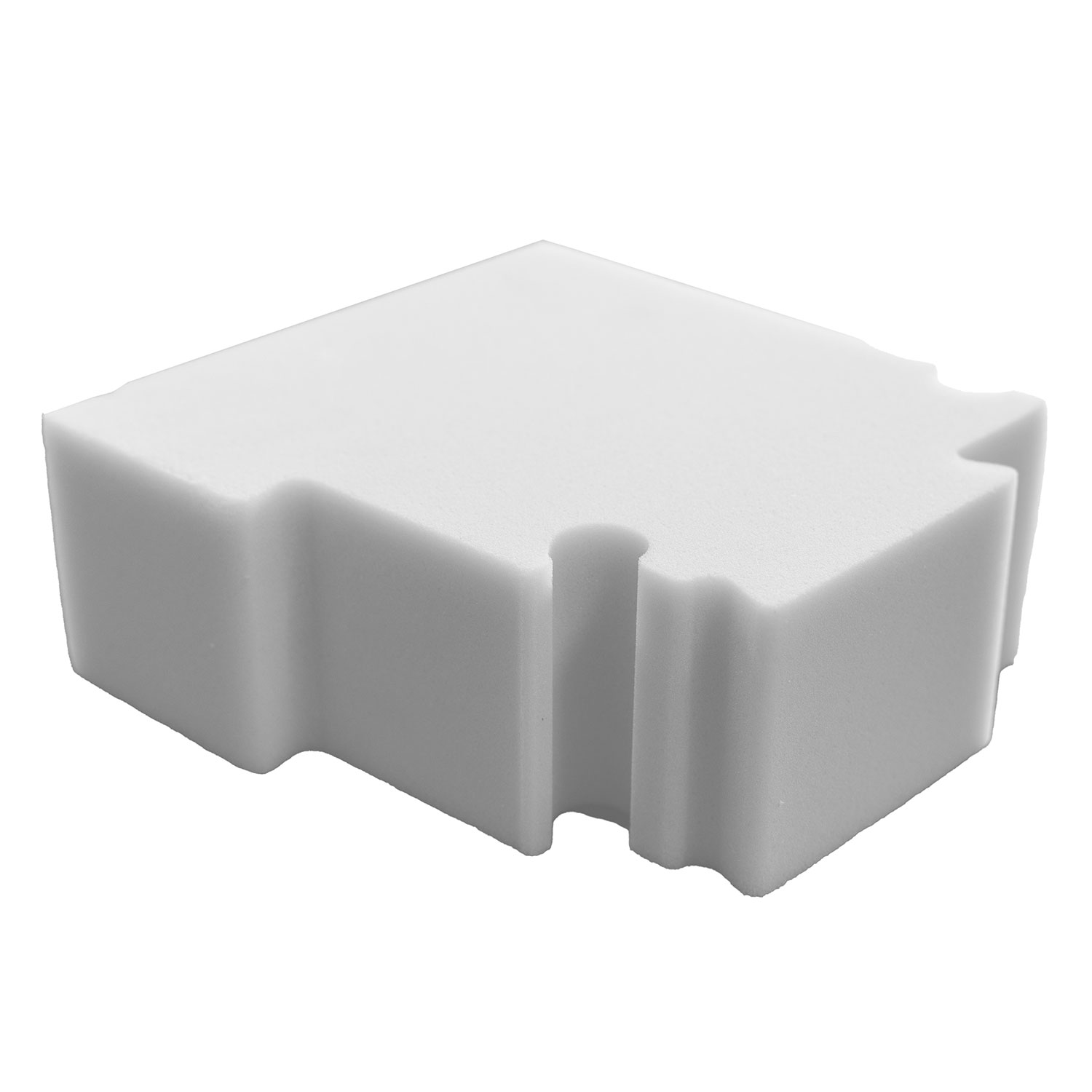

It possesses inherent flame retardancy and excellent properties such as sound absorption and noise reduction, thermal insulation, cushioning, and shock absorption, as well as environmental safety.

It finds wide applications in various fields such as cold insulation materials for rail transit, flame retardant and sound absorbing materials for buildings, pipeline insulation and noise reduction materials, and equipment cushioning and thermal insulation materials.

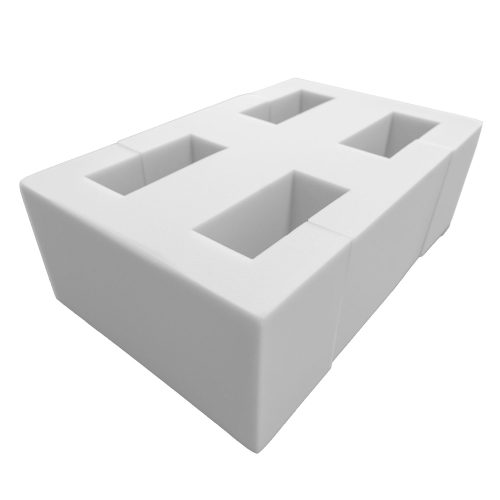

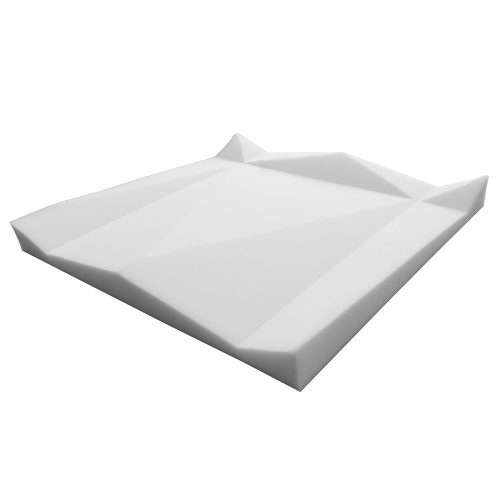

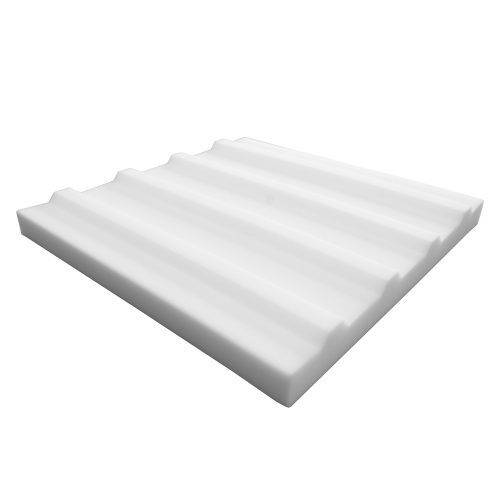

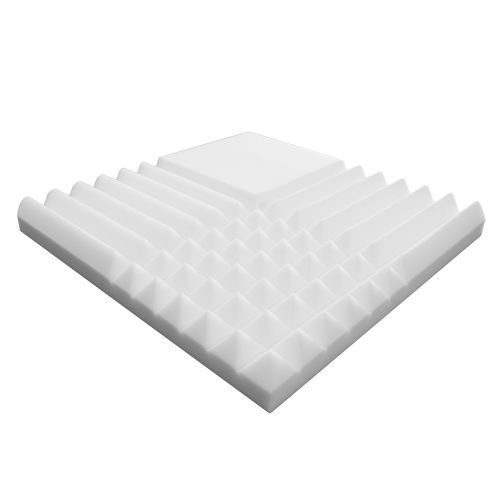

Its outstanding secondary processing capability enables it to be used in various forms for acoustic treatment and noise control in venues such as hotels, schools, hospitals, sports arenas, and auditoriums.

Key Properties of Melamine Foam

- Microporous Structure – The foam consists of a hard, open-cell structure that acts like ultra-fine sandpaper when wet, making it effective at removing tough stains.

- Abrasive Yet Gentle – While it works similarly to very fine sandpaper, it is soft enough not to damage most hard surfaces (though it can scratch glossy or delicate finishes if used too aggressively).

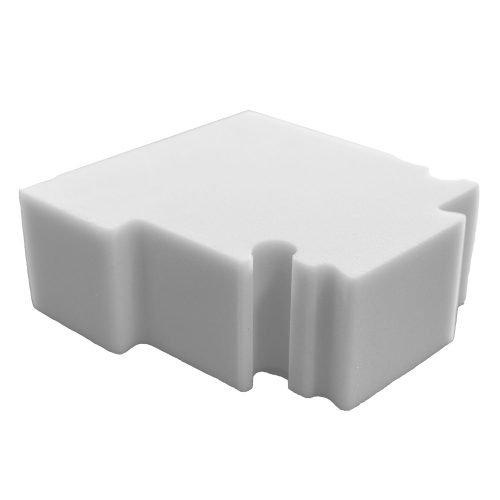

- High Hardness & Low Density – Despite being lightweight, the foam is rigid and retains its shape under pressure.

- Thermal & Sound Insulation – Due to its porous structure, it has good heat resistance (up to ~200°C) and sound-absorbing properties.

- Chemical Resistance – Resistant to many solvents, making it useful in industrial applications.

If you have any questions, please leave your contact details for prompt assistance.